Clever jig for the bandsaw

Posted: Sun Aug 09, 2015 4:40 pm

I finally got around to reading a book on bandsaws I bought a couple of years ago. In it is a description of a jig that acts as a fence, but has micro-adjustment. Thinking this would be useful for sawing kerfs and laminations, I decided to have a go.

In essence, it's two tapered components that when aligned, have parallel outer edges. As you slide the two blocks against each other, the outside edges get closer or further apart. bolt going through a bracket secures them in place. A vertical board becomes the fence face.

This was just a prototype. I think I will make another, such that the adjustment is even finer. This one has 2 mm of fence adjustment for every 10 mm of block movement. An adjustment ratio of 1:10 would be better.

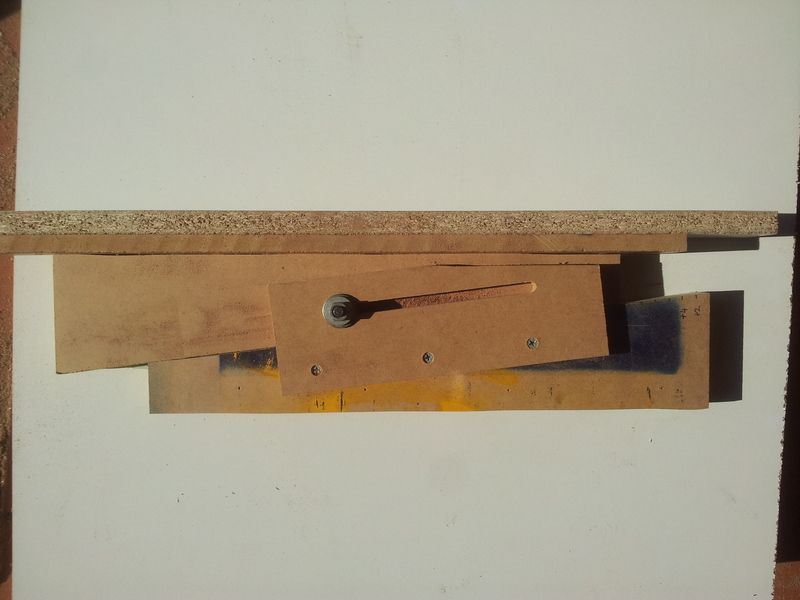

Fence at the top, bird's eye view. This is at full 'contraction':

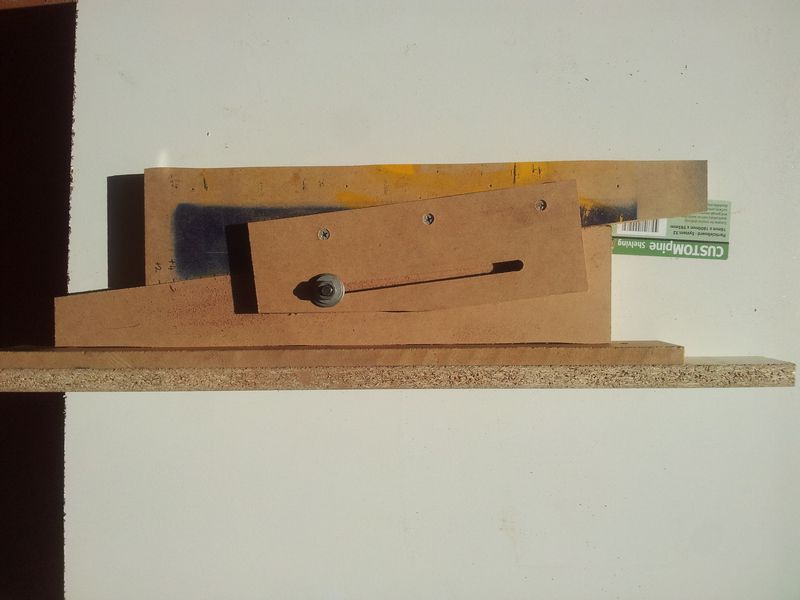

mid range:

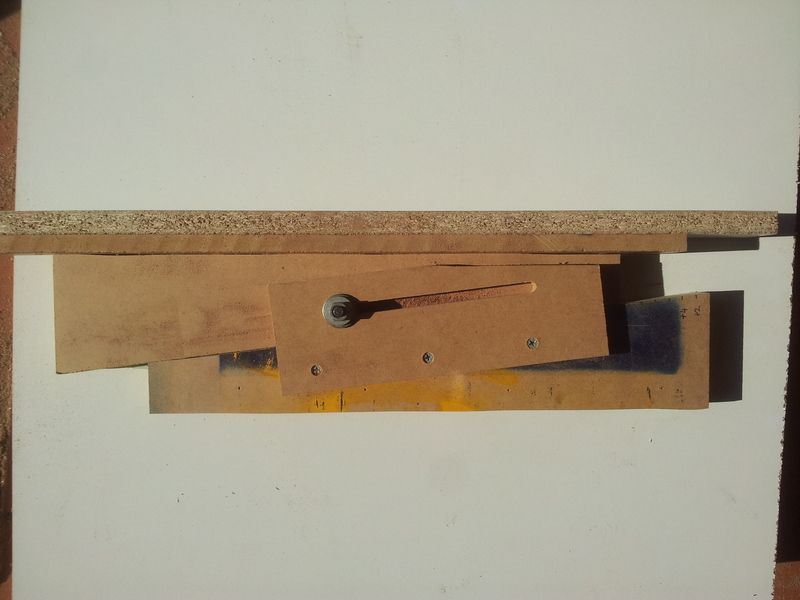

As wide as it will go:

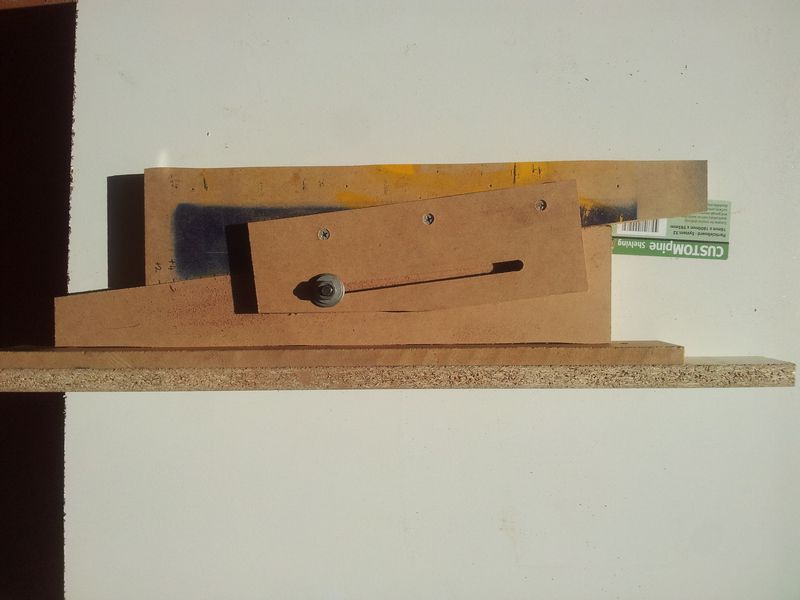

on the saw:

Incidentally, I think my current bandsaw blade is poor. The blade material is very, very thin. But that's not the problem. The problem is that the teeth don't seem to have much set on them. This makes for a 0.5 mm kerf, which is just barely wider than the blade. This, in turn (I suspect) is the reason that despite being 3/8" wide, this blade struggles to cut curves accurately, and struggles to cut straight lines unless the fence is set perfectly.

That aside, this jig is the execution of terrific concept. Micro-adjust fences can be quite expensive to buy, but this was all made from scrap I had lying around. I believe a jig like this can be made to be every bit as accurate as a manufactured one.

In essence, it's two tapered components that when aligned, have parallel outer edges. As you slide the two blocks against each other, the outside edges get closer or further apart. bolt going through a bracket secures them in place. A vertical board becomes the fence face.

This was just a prototype. I think I will make another, such that the adjustment is even finer. This one has 2 mm of fence adjustment for every 10 mm of block movement. An adjustment ratio of 1:10 would be better.

Fence at the top, bird's eye view. This is at full 'contraction':

mid range:

As wide as it will go:

on the saw:

Incidentally, I think my current bandsaw blade is poor. The blade material is very, very thin. But that's not the problem. The problem is that the teeth don't seem to have much set on them. This makes for a 0.5 mm kerf, which is just barely wider than the blade. This, in turn (I suspect) is the reason that despite being 3/8" wide, this blade struggles to cut curves accurately, and struggles to cut straight lines unless the fence is set perfectly.

That aside, this jig is the execution of terrific concept. Micro-adjust fences can be quite expensive to buy, but this was all made from scrap I had lying around. I believe a jig like this can be made to be every bit as accurate as a manufactured one.