First LamBow buildalong. Very long. Lots of photos.

Moderator: Moderators

First LamBow buildalong. Very long. Lots of photos.

Heya.

I thought I'd share a Laminated Flatbow build I recently completed.

I'm a little self-conscious about posting this as it isn't anything particularly special. It's a run-of-the-mill, bog standard laminated flatbow.

HOWEVER, it's the first serious bow that I've made and I'm hoping to encourage anyone thinking of trying their hand at bowmaking for the first time. In this writeup you'll find, what I did. What I did WRONG and what I need to improve on. And in the end, the result turned out OK.

I prepared for this by lurking on various forums for well over a year. Reading everything I could on their construction. Buying the John Clark book on Flatbow construction and trying my hand at a practice Booboard flatbow as a practice project - to get some of the skills under my belt. That booboard was documented

http://www.ozbow.net/phpBB3/viewtopic.php?f=34&t=9590

The construction of this bow took ages as I had very limited time to work on it (Saturdays only mostly). I planned (or at least thought about) each step in detail, carefully put it together, then discussed the results with Greybeard - a gentleman whos advice was very helpful over the course of this project, the following week.

My intention was to create a very Vanilla bow. No fancy ascents in the riser. No reflex or deflex. Just a plain flatbow that I could use as a baseline for comparison when I go on to make new, and more complex bows in the future.

edit: Reddit verification: NuArcher.

I thought I'd share a Laminated Flatbow build I recently completed.

I'm a little self-conscious about posting this as it isn't anything particularly special. It's a run-of-the-mill, bog standard laminated flatbow.

HOWEVER, it's the first serious bow that I've made and I'm hoping to encourage anyone thinking of trying their hand at bowmaking for the first time. In this writeup you'll find, what I did. What I did WRONG and what I need to improve on. And in the end, the result turned out OK.

I prepared for this by lurking on various forums for well over a year. Reading everything I could on their construction. Buying the John Clark book on Flatbow construction and trying my hand at a practice Booboard flatbow as a practice project - to get some of the skills under my belt. That booboard was documented

http://www.ozbow.net/phpBB3/viewtopic.php?f=34&t=9590

The construction of this bow took ages as I had very limited time to work on it (Saturdays only mostly). I planned (or at least thought about) each step in detail, carefully put it together, then discussed the results with Greybeard - a gentleman whos advice was very helpful over the course of this project, the following week.

My intention was to create a very Vanilla bow. No fancy ascents in the riser. No reflex or deflex. Just a plain flatbow that I could use as a baseline for comparison when I go on to make new, and more complex bows in the future.

edit: Reddit verification: NuArcher.

Last edited by ppofandt on Tue Oct 02, 2012 2:27 am, edited 2 times in total.

Re: First LamBow buildalong. Very long. Lots of photos.

I started with a set of materials purchased from Ausbow.

4 pairs of core laminations, Bubinga riser block & 2 lengths of black fibreglass.

While reading up (memorising actually) on the construction steps that would be coming, I made up a simple gluing form. A straight length of 40mm wide pine, 2m long. I added a series of flat washers on the sides to act as guides and screwed in a number of hooks that I would use to wrap rubber strips around. The rubber strips would be acting as make-do pressure clamps when gluing.

I also cut the thick ends of each of the core laminations (I'll call them lams now for short) at 45deg. so that the joins, when they were all stacked on the form, would not all line up. Staggering the joins as it were. I also made sure that the ends were clean and square to each other and that there were no gaps when laid end-to-end.

Next step was a dry run. Putting all the components onto the form sans glue. It all went together well and there were no gaps that I could see. However, I decided to add a lot more rubber to the form when the time came to do the final glueup.

The pressure strip on the riser came courtesy of one of my old neoprene stubby holders. I also added 2 small strips of pine to either side of the riser block to keep it properly centred. The riser block being only 30mm wide while the form and lams were 40mm.

4 pairs of core laminations, Bubinga riser block & 2 lengths of black fibreglass.

While reading up (memorising actually) on the construction steps that would be coming, I made up a simple gluing form. A straight length of 40mm wide pine, 2m long. I added a series of flat washers on the sides to act as guides and screwed in a number of hooks that I would use to wrap rubber strips around. The rubber strips would be acting as make-do pressure clamps when gluing.

I also cut the thick ends of each of the core laminations (I'll call them lams now for short) at 45deg. so that the joins, when they were all stacked on the form, would not all line up. Staggering the joins as it were. I also made sure that the ends were clean and square to each other and that there were no gaps when laid end-to-end.

Next step was a dry run. Putting all the components onto the form sans glue. It all went together well and there were no gaps that I could see. However, I decided to add a lot more rubber to the form when the time came to do the final glueup.

The pressure strip on the riser came courtesy of one of my old neoprene stubby holders. I also added 2 small strips of pine to either side of the riser block to keep it properly centred. The riser block being only 30mm wide while the form and lams were 40mm.

Re: First LamBow buildalong. Very long. Lots of photos.

Glueup time. I was more than a little nervous here as this was a one way process. Excited but nervous. No going back once started. Exceited but nervous. I mixed up the 2 parts of the Epoxy (Techniglue) - probably making too much but for a first time run I preferred too much to too little. I covered the form itself in strips of clear packing tape in preparation. I laid out all the lams in the order that they would go onto the form and, early one Saturday morning - while it was still very cold (Techniglue cures faster in hot weather. Cold weather would give me more time to work) got started on the glueup.

I decided to do the glueup in 2 stages. Bottom (back) layer of glass, 3 core layers and riser to start with. Then later the last core lam and belly glass.

I buttered the epoxy onto the back of the glass to start with, then onto one side of a lam and laid the two together on my benchtop. Then buttered more epoxy onto that, then another lam, laid it on etc. THEN put the whole set onto the form to apply pressure. Another layer of plastic film (Cling Wrap this time) went over the lams to prevent the rubber from sticking.

This is where I made my first mistake. In my nervous haste to get everything glued together and on the form before the epoxy started curing, I neglected to check that the ends of the lams - where they butt together, STAYED together after I had laid them onto the form. As it turned out they had separated a little resulting in some ugly glue lines. A few seconds checking them and a little pressure at the tips would have sorted that out right but my inexperience caused me to miss this. Something I WON'T forget next time. Score 1 for experience.

I clamped down the lams using strips of rubber, crisscrossing the form side to side along the length of the form. Extra strips of rubber at the riser fadeout (the then end of the riser block) for stronger clamping power. Then I left it in my shed to cure. As anyone in the Australian climate can probably attest to, a galv iron shed can get pretty hot durring the day if it's in full sunlight. I left it for 24 hours before unwrapping it and sanding the glue away from the sides to get a look at the glue lines.

The following weekend I added on the last core lam and the belly layer of glass. Cooked it, stripped it out of the form and cleaned it up.

There was a small void at the edge of the riser between the riser itself and the lam. It didn't go all the way through and hopefully would disappear when the riser was shaped (it did). If not, I was going to fill it with Superglue gel and sand it down.

I decided to do the glueup in 2 stages. Bottom (back) layer of glass, 3 core layers and riser to start with. Then later the last core lam and belly glass.

I buttered the epoxy onto the back of the glass to start with, then onto one side of a lam and laid the two together on my benchtop. Then buttered more epoxy onto that, then another lam, laid it on etc. THEN put the whole set onto the form to apply pressure. Another layer of plastic film (Cling Wrap this time) went over the lams to prevent the rubber from sticking.

This is where I made my first mistake. In my nervous haste to get everything glued together and on the form before the epoxy started curing, I neglected to check that the ends of the lams - where they butt together, STAYED together after I had laid them onto the form. As it turned out they had separated a little resulting in some ugly glue lines. A few seconds checking them and a little pressure at the tips would have sorted that out right but my inexperience caused me to miss this. Something I WON'T forget next time. Score 1 for experience.

I clamped down the lams using strips of rubber, crisscrossing the form side to side along the length of the form. Extra strips of rubber at the riser fadeout (the then end of the riser block) for stronger clamping power. Then I left it in my shed to cure. As anyone in the Australian climate can probably attest to, a galv iron shed can get pretty hot durring the day if it's in full sunlight. I left it for 24 hours before unwrapping it and sanding the glue away from the sides to get a look at the glue lines.

The following weekend I added on the last core lam and the belly layer of glass. Cooked it, stripped it out of the form and cleaned it up.

There was a small void at the edge of the riser between the riser itself and the lam. It didn't go all the way through and hopefully would disappear when the riser was shaped (it did). If not, I was going to fill it with Superglue gel and sand it down.

Re: First LamBow buildalong. Very long. Lots of photos.

That done I stripped off the masking tape protecting the glass (was getting a bit tatty by that stage), added new masking tape and marked out the centre line and shape.

Rather than subject my rather underpowered bandsaw to the job of cutting it to shape I used a couple of new 80grit sanding belts and a few hours of elbow grease to sand it down to shape. As someone posted here - a few sanding belts are a LOT cheaper than a new bandsaw band.

Rather than subject my rather underpowered bandsaw to the job of cutting it to shape I used a couple of new 80grit sanding belts and a few hours of elbow grease to sand it down to shape. As someone posted here - a few sanding belts are a LOT cheaper than a new bandsaw band.

Re: First LamBow buildalong. Very long. Lots of photos.

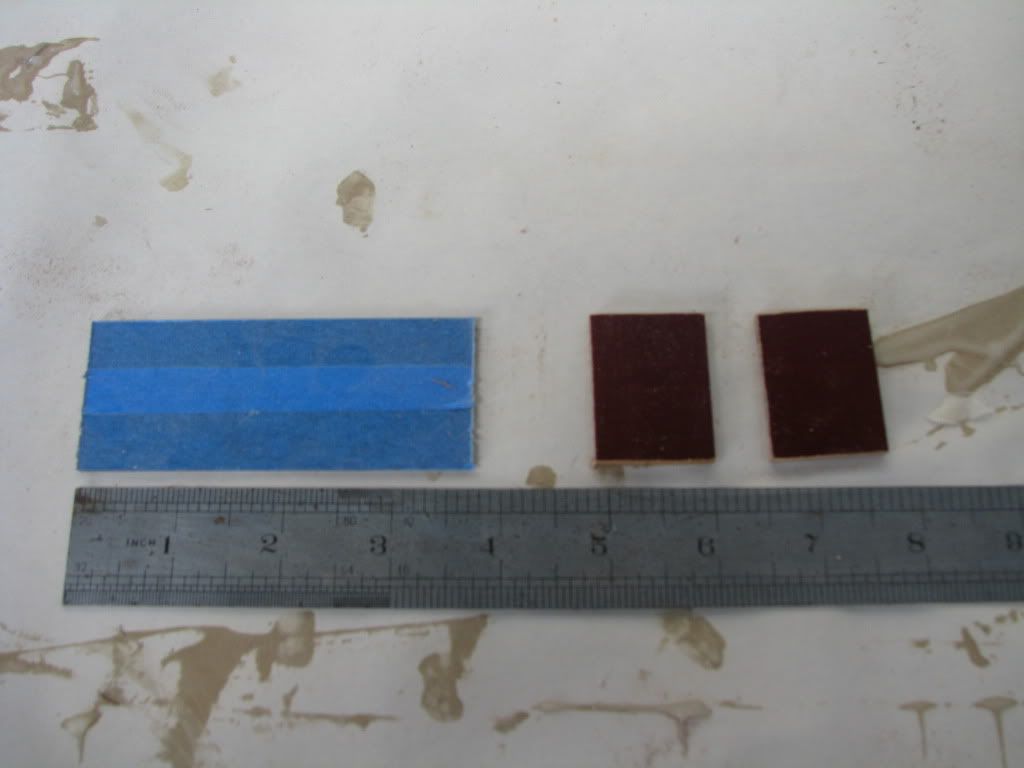

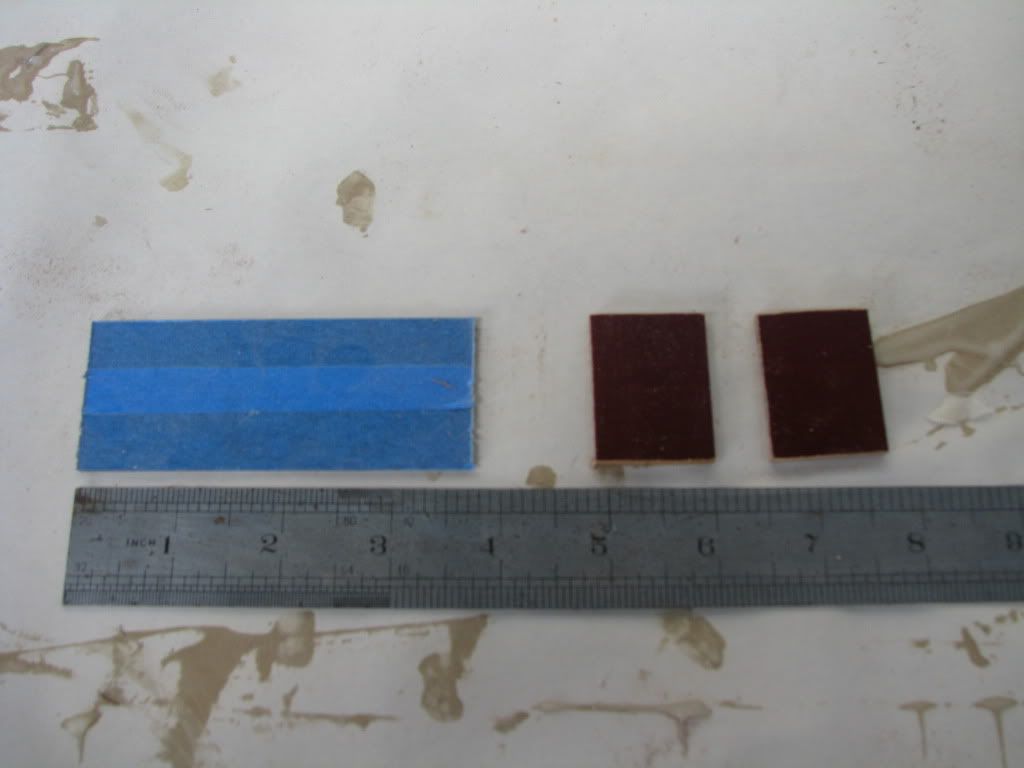

Now. Nock tip overlays. My materials included a piece of phenolic - resin impregnated cloth. However I was rather impressed with the look I saw in another build-along where the bowmaker used some extra backing glass with a layer of wood on top. With that in mind I took stock of what materials I had on hand - 2pcs phenolic and a couple of inches of leftover glass.

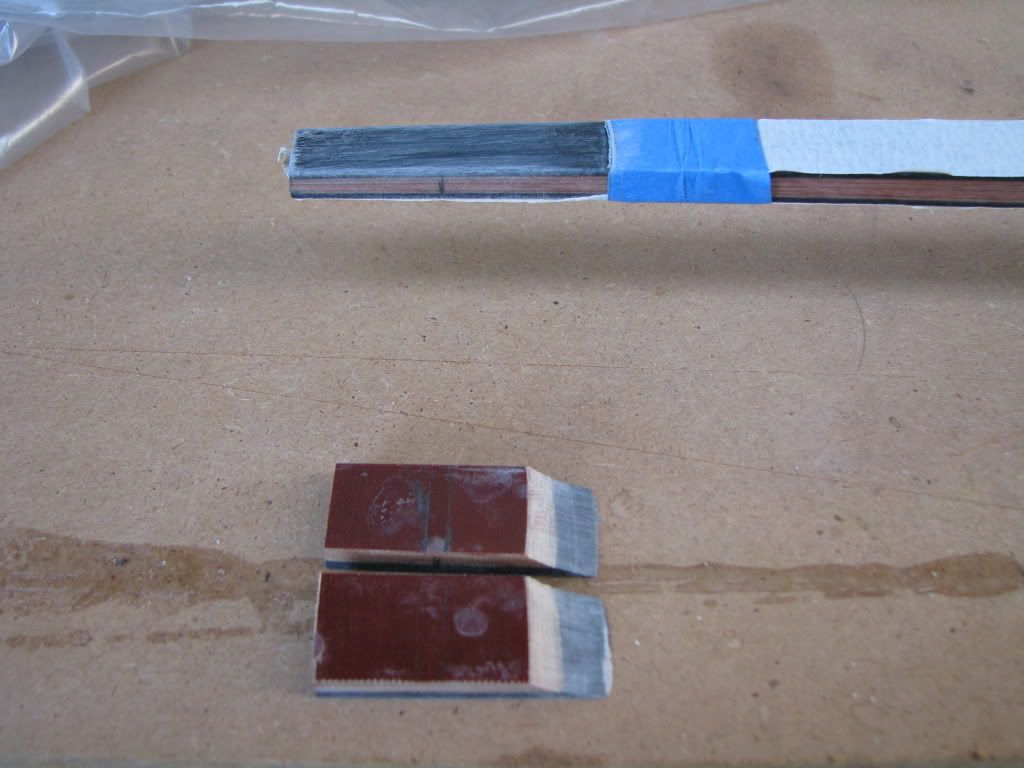

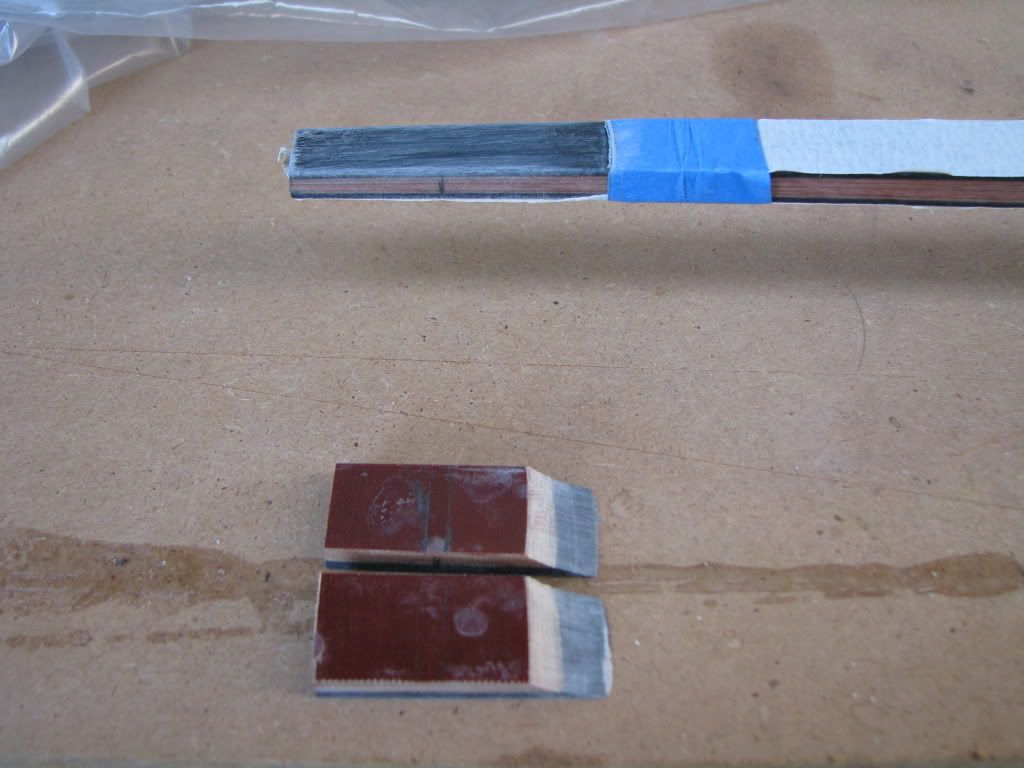

and put together a set of nock overlays. Glass - glass & phenolic - in that order. Glued them together and rough shaped them.

I peeled back the masking tape and roughed up the surface with an old hacksaw blade and glued on the tips.

DOUBLE CHECKING this time that there was no shifting once pressure was applied.

and put together a set of nock overlays. Glass - glass & phenolic - in that order. Glued them together and rough shaped them.

I peeled back the masking tape and roughed up the surface with an old hacksaw blade and glued on the tips.

DOUBLE CHECKING this time that there was no shifting once pressure was applied.

Re: First LamBow buildalong. Very long. Lots of photos.

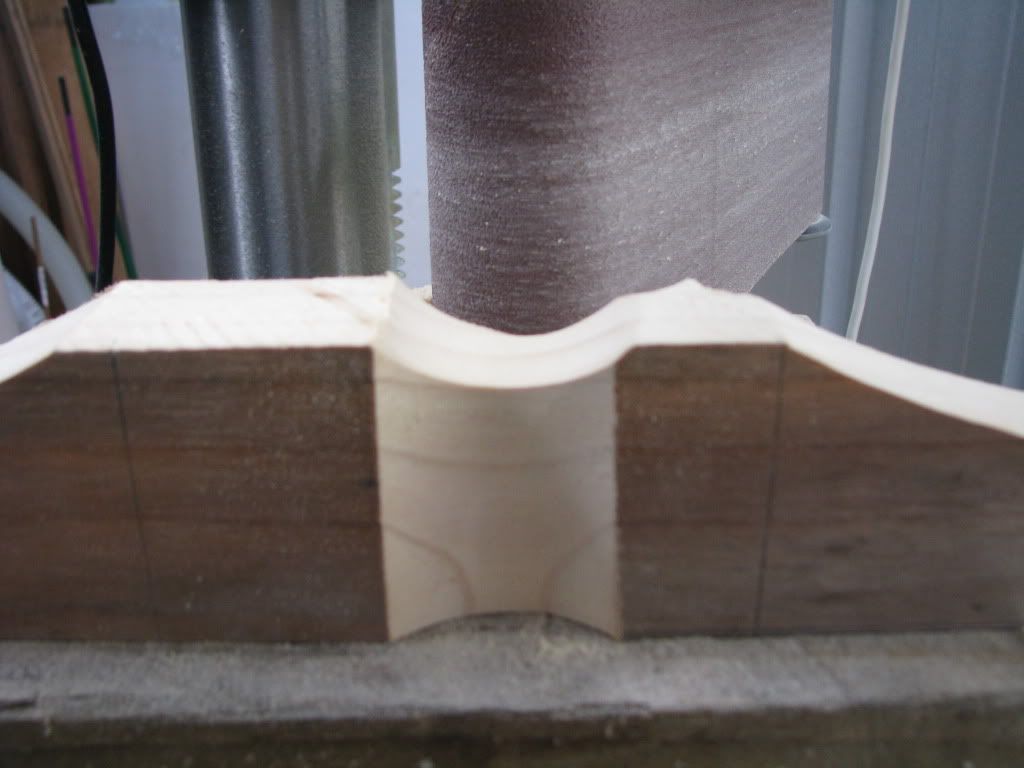

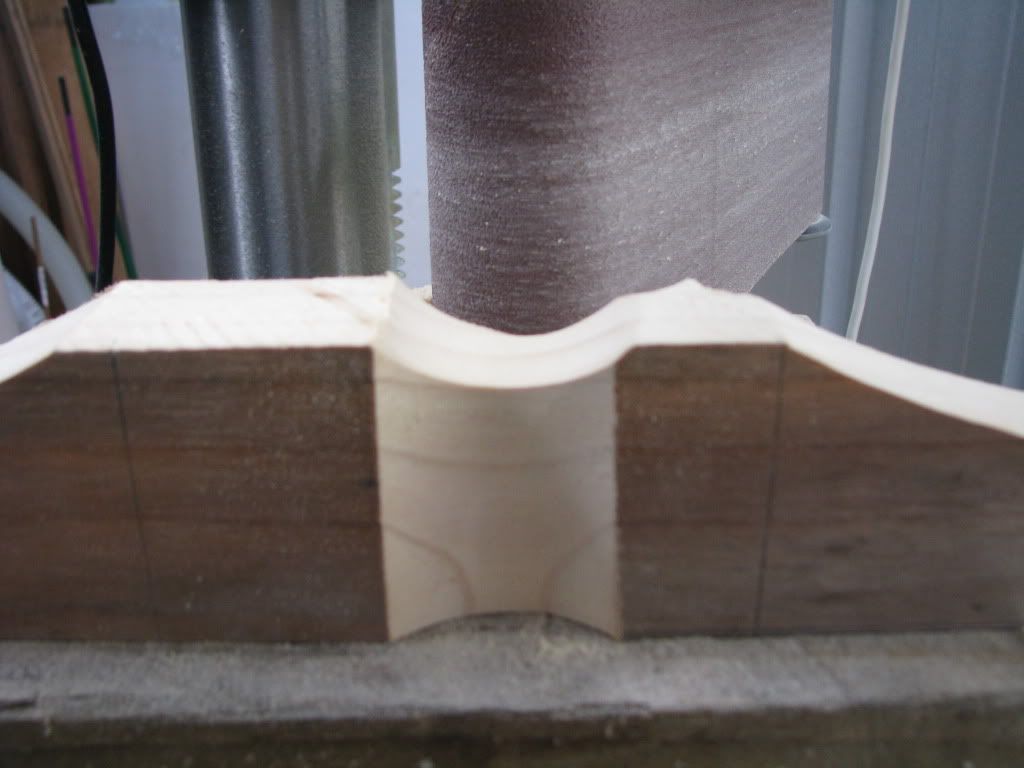

The next stage coming up was shaping the riser. This is a critical step and another of the "No going back" stages. Once I remove some of the riser wood there's no putting it back.

so I traced out the shape of the riser section onto some framing pine and made a few practice risers. I'm seriously glad I did as the first riser I made I found that I'd cut it for a LEFT hander - not the right I'd intended.

Ah well. That's what practice jobs are for.

In all I made about 4 sets of practice risers. Refining the construction. Simplifying and reducing the process to a few simple steps.

Grind 2 indents on the left and right side (final version I made them parallel)

Join them across the belly with a third indent - slightly deeper than the other two.

Then smooth and soften all the edges.

I kept the shaping of the riser minimal on the basis that I can always remove more wood later.

so I traced out the shape of the riser section onto some framing pine and made a few practice risers. I'm seriously glad I did as the first riser I made I found that I'd cut it for a LEFT hander - not the right I'd intended.

Ah well. That's what practice jobs are for.

In all I made about 4 sets of practice risers. Refining the construction. Simplifying and reducing the process to a few simple steps.

Grind 2 indents on the left and right side (final version I made them parallel)

Join them across the belly with a third indent - slightly deeper than the other two.

Then smooth and soften all the edges.

I kept the shaping of the riser minimal on the basis that I can always remove more wood later.

Re: First LamBow buildalong. Very long. Lots of photos.

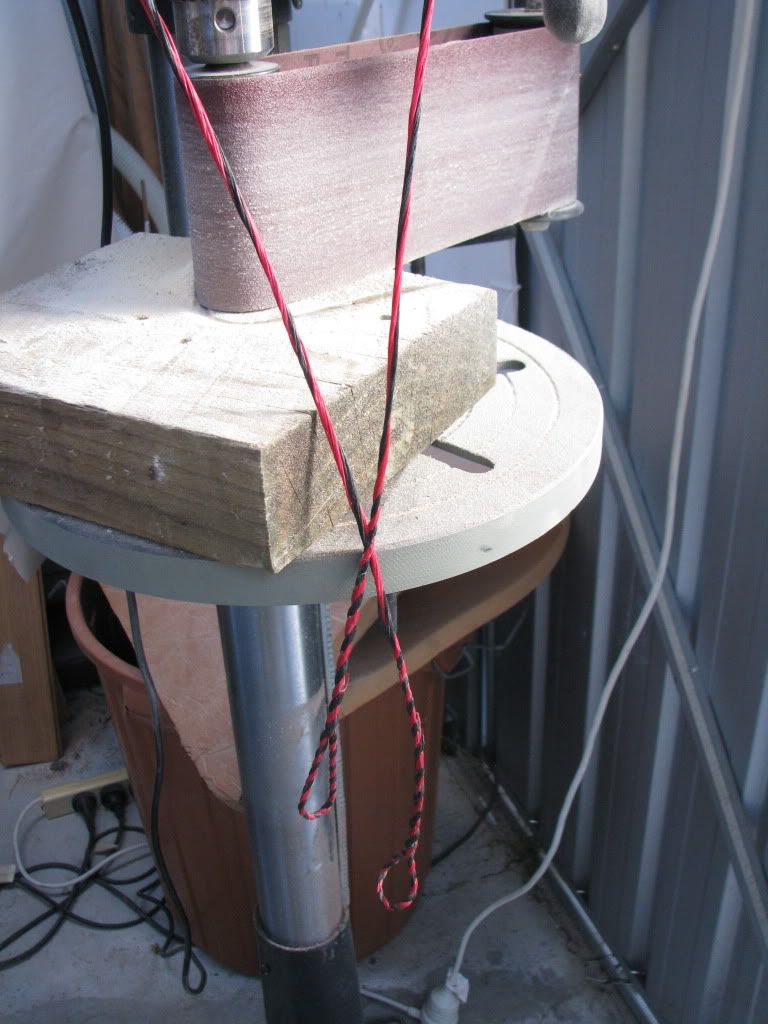

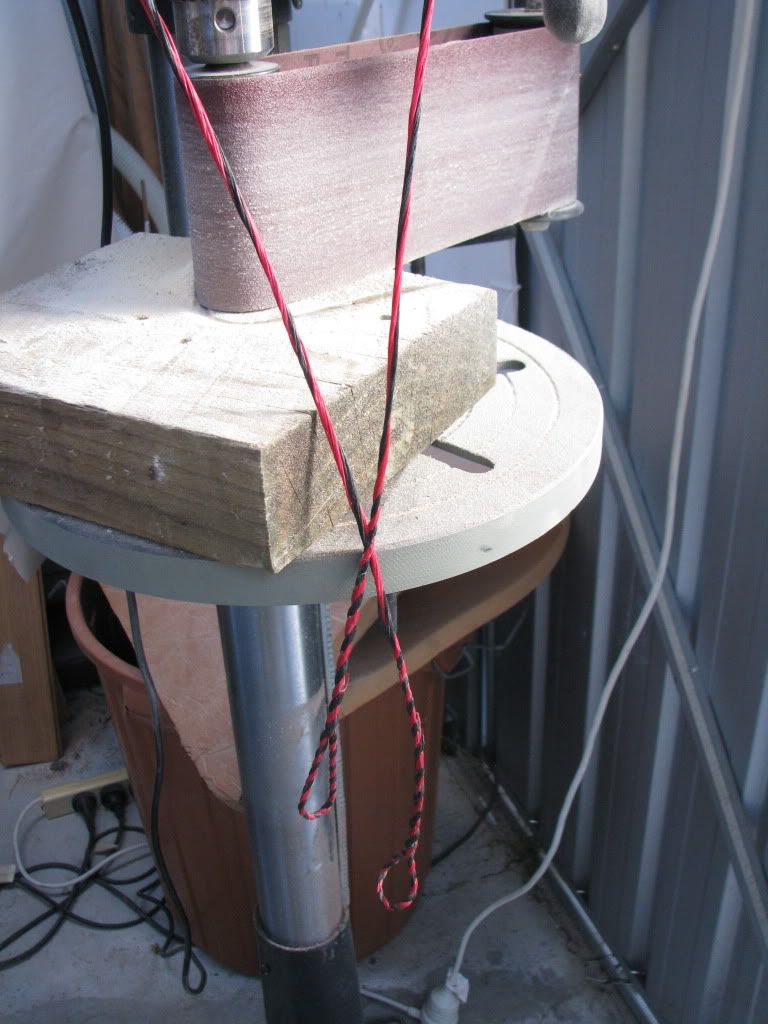

While working on that I also finished a quick Flemmish String making jig and made a few strings following the excellent guide here:

http://www.youtube.com/watch?v=EXaUxSqu63o

My first string seemed to turn out quite suitable (loops were a bit too big. I made another string later)

I cut the string grooves and smoothed out any sharp edges (smoothed it out more later). I was a little worried that I had cut the back groove too deep. Or at least deeper than needed. But I only just begun to cut into the two layers of overlay glass. Original back glass hadn't even been touched so I figured that should be ok.

And braced it for the first time. Congratulations Sir. It's a Bow!!

From there I spent time further shaping the tips. I'll spare you the photos as this is getting very long as it is - sorry bout that.

http://www.youtube.com/watch?v=EXaUxSqu63o

My first string seemed to turn out quite suitable (loops were a bit too big. I made another string later)

I cut the string grooves and smoothed out any sharp edges (smoothed it out more later). I was a little worried that I had cut the back groove too deep. Or at least deeper than needed. But I only just begun to cut into the two layers of overlay glass. Original back glass hadn't even been touched so I figured that should be ok.

And braced it for the first time. Congratulations Sir. It's a Bow!!

From there I spent time further shaping the tips. I'll spare you the photos as this is getting very long as it is - sorry bout that.

Re: First LamBow buildalong. Very long. Lots of photos.

I shaped the riser as I planned. Marked out the arrow shelf starting at 2" above center. I marked a line from the edge of the limb - 3" up from the top of the shelf down to 3/8" in at the shelf. Made a series of cuts most of the way down to the line with a hacksaw and chiselled the wood out. Sanded and rasped the resulting window smooth and free of toolmarks. I seem to have missed a few photos here but the results were pleasing.

Next I ground the grip indentations as planned.

Then gradually smoothed out all the edges.

The resulting riser felt comfortable in the hand and easy to shoot.

Next I ground the grip indentations as planned.

Then gradually smoothed out all the edges.

The resulting riser felt comfortable in the hand and easy to shoot.

Re: First LamBow buildalong. Very long. Lots of photos.

Over the next few days I gradually sanded it down smoother and smoother - with increasingly fine grades of sandpaper.

I sprayed it with a polyurethane based clear coat and buffed it down between coats with 0000 steel wool - that was a learning experience too. Never sealed anything like this before and I learned a LOT about how NOT to do it. Lots of sanding back and re-sealing.

The resulting finish is a very pleasant rich red colour - contrasting nicely with the black glass.

49# at 28" - about what I was hoping for (original aim was for 45#)

Now I just need to source a few good arrows to compliment this and start practicing.

My apologies for the length of this post. For a beginner I thought this turned out fairly well. I'm already planning my next project. Hopefully other forum lurkers will take this as a positive example and have a go themselves.

I'd appreciate any criticism people may have to offer. So please have your say.

I've left out a good amount of the photos I took. If you're really interested in the full collection, go Here and step your way through the full set.

Cheers.

Paul.

I sprayed it with a polyurethane based clear coat and buffed it down between coats with 0000 steel wool - that was a learning experience too. Never sealed anything like this before and I learned a LOT about how NOT to do it. Lots of sanding back and re-sealing.

The resulting finish is a very pleasant rich red colour - contrasting nicely with the black glass.

49# at 28" - about what I was hoping for (original aim was for 45#)

Now I just need to source a few good arrows to compliment this and start practicing.

My apologies for the length of this post. For a beginner I thought this turned out fairly well. I'm already planning my next project. Hopefully other forum lurkers will take this as a positive example and have a go themselves.

I'd appreciate any criticism people may have to offer. So please have your say.

I've left out a good amount of the photos I took. If you're really interested in the full collection, go Here and step your way through the full set.

Cheers.

Paul.

-

longbow steve

- Posts: 3116

- Joined: Tue Jan 30, 2007 3:29 pm

- Location: BLUE MOUNTAINS

Re: First LamBow buildalong. Very long. Lots of photos.

Happy birthday for starters  . You have done a good job for your first bow and I am sure your build along will give inspiration to others.

. You have done a good job for your first bow and I am sure your build along will give inspiration to others.

Steve

Steve

- Gringa Bows

- Posts: 6331

- Joined: Thu Aug 30, 2007 7:09 pm

- Location: Bundaberg QLD

Re: First LamBow buildalong. Very long. Lots of photos.

looks pretty good for your first one,the bubinga is nice timber too.........and Happy Birthday..

Re: First LamBow buildalong. Very long. Lots of photos.

Looks good mate, I like your handle design that looks different...Roscoe

Re: First LamBow buildalong. Very long. Lots of photos.

Very good job on the bow.

Is that your first bow ever or have you done selfbows before?

If it's your first bow ever, bloody good job for a first one.

Nice tips, shape of handle is alright, handles are a very personal thing.

Nice finish.

Good on ya!

Alex.

Is that your first bow ever or have you done selfbows before?

If it's your first bow ever, bloody good job for a first one.

Nice tips, shape of handle is alright, handles are a very personal thing.

Nice finish.

Good on ya!

Alex.

- Stickbow Hunter

- Supporter

- Posts: 11637

- Joined: Sat Jul 26, 2003 8:33 pm

- Location: Maryborough Queensland

Re: First LamBow buildalong. Very long. Lots of photos.

Congrats mate and well done!!! Thank you for taking the time to post up your build-a-long. There is no reason for appologizing for its length as it all helps to show others and encourage them to also have a go. My only critizism is that you used a photo hosting site (photobucket) for posting the photos. When you clear your photos from there they will no longer be available here to help out others wanting to make their own bow. I encourage everyone to upload their photos direct to the site so they are always available for others to see as a great article such as this one really isn't much use without photos.

A couple of things to consider next time:

If you order a kit from Clarkey again get him to give you a riser that is also 40mm wide. Why he insists on making them 30mm wide is beyond me. This will make things much easier you you IMO.

This will make things much easier you you IMO.

Try gluing your half lams together before you glue the bow up - stops any slippage like you got with this one.

Consider gluing up in one process - much simpler and much less work IMO.

Once again excellent result for your first effort!!!

Jeff

A couple of things to consider next time:

If you order a kit from Clarkey again get him to give you a riser that is also 40mm wide. Why he insists on making them 30mm wide is beyond me.

Try gluing your half lams together before you glue the bow up - stops any slippage like you got with this one.

Consider gluing up in one process - much simpler and much less work IMO.

Once again excellent result for your first effort!!!

Jeff

Re: First LamBow buildalong. Very long. Lots of photos.

Nice work Paul, I will be happy if my first bow looks that good. Thanks for your efforts, great build-along.

Cheers......Rod

Cheers......Rod

Re: First LamBow buildalong. Very long. Lots of photos.

I'm not yet sure I like the riser design. It's not... I have no idea. But I've seen some beautiful fluid designs.roscoe wrote:Looks good mate, I like your handle design that looks different...Roscoe

I'll play with it a bit more till I'm satisfied. Like I said - I can always take off more later.

First bow ever. Not counting the Boo Board bow I made prior since that was just to practice a few of the skills. Not what I'd call a real bow. Not shootable anyway.If it's your first bow ever, bloody good job for a first one.

Nice tips, shape of handle is alright, handles are a very personal thing.

Nice finish.

The tips came out very nicely. I was a bit concerned about the phenolic as it looked a bit tatty at first. but once it was properly sanded and sealed, it came out as a lovely honey colour.

The handle was shaped to fit my hand and to minimise the possibility of me stuffing it up. Absolutely minimal cutting on it.

The finish came out beautifully. lovely silky matt finish to the glass. Beautiful colour to the riser. Bubinga is a VERY nice wood to work on. I'm going to be using it again I think - unless I can get my hands on some Jarah.

Ya. I'm aware of the problems with external hosting sites. Bane of my research career - as it were. So many build alongs with generic "Photo no longer hosted" thumbnails where the pics should be. However I was uncertain as to the limits of what I could host here. If I get the time I'll upload the relevant photos here and edit the posts to point to the local photos.My only critizism is that you used a photo hosting site (photobucket) for posting the photos

That said - I take the responsibility of posting a photo-documented build along seriously and don't intend to remove the photos until I'm forced to.

Absolutely. I'd already come to that conclusion. Next time I'll tack them together with a bit of superglue or similar before gluing up. I'll also probably do the whole glueup in one go next time too. Especially now that I have a better idea how much time I have to work with. Less panicking next timeTry gluing your half lams together before you glue the bow up - stops any slippage like you got with this one.

Consider gluing up in one process - much simpler and much less work IMO.

Thanks to everyone for your kind words.

At the moment I'm in the process of developing the design for a simple boardbow I can "mass produce" for my wife's scouts group. She wants to do an archery class and get them to make their own bows. I'm trying a few designs out to find a suitable pyramid type bow that I can make in bulk and with minimal complexity. After that - a new bow is in order I think

Cheers.

-

ivorycollector

Re: First LamBow buildalong. Very long. Lots of photos.

Congratulations on a very fine looking bow. No turning back now  Cheers.

Cheers.